The team took a tour through the Concrete and Materials Branch, which is part of the Geotechnical Structures Laboratory here at ERDC. Our mentors, Mr. Cody and Mr. Hayden, work with the Additive Manufacturing Group within the Concrete and Materials Branch. The branch has many 3D printers, big and small. One of the first things we saw was a giant 3D printer housed inside three twenty-foot-long cargo shipping containers. The printer can print in metals and plastic. The lab also has a 3D printer that prints using sand which they use to make molds, and another printer that could implant carbon fibers into what it was printing which can greatly increase the stiffness of the part. They also had a resin printer, which is still a 3D printer. It just uses a liquid resin to print with instead of a solid polymer plastic like the ones most people are familiar with.

As our mentors walked us through the branch, we got the chance to touch some of the things that they printed like some 3D-printed sand molds. They also had carbon fiber designs that you can’t just cut out of sheet metal that we could touch, and samples of different concrete they had made. The branch also has a huge 3D-printed bridge girder. While not 3d printed, it’s a composite made of fiber glass, carbon fiber, and resin. The mold that was used to make it however, was 3d printed and is 40 ft long. There are actually three bridges in service now using these. The girders weigh about 1200 lbs, which is roughly 1/4 the weight of their steel and concrete counterparts.The University of Maine printed it for the Concrete and Materials Branch with one of the largest 3D printers in the world.

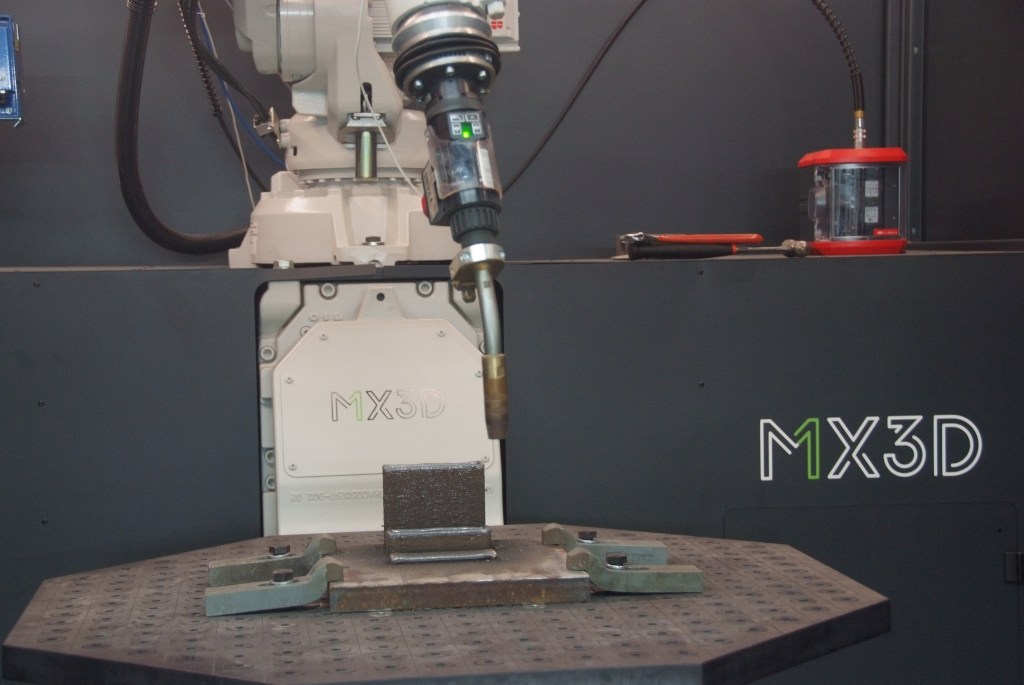

While the branch mostly works in concrete, they also work with many other materials such as metals and alloys. In one part of the lab there is a mixing pot nicknamed “the Arc Melting Furnace”. It’s used to make metal alloys using a welder to create an arc of electricity to join the base metals together. Also, they have a robot mig welder called the MX1 that it is from the Netherlands. It is the first one of its kind in the US. The welder has a revolving base has a laser thermometer to keep an eye on the temperature. There are also cameras so the operator can see what’s going on inside the print enclosure.

Thank you to Mr. Cody and Mr. Hayden for the Concrete and Materials Branch tour. It was a very educational experience, and our team learned a lot from it. If you would like to learn more about STEAM, you can join our team by contacting us on Facebook or through email, or you can call or text our Coach, Mr. Cody, at 601.618.4750. We are looking forward to learning more about STEAM fields and their real-world applications in the future.